For DC spot welding/fusing: IS-300A

- ◆Compact and 1.5 times higher output than that of the conventional model IS-120B.

- ◆Detailed weld schedules can be set.

◆Transformer selecting function-

Six control types

You can choose from; "Primary constant-current RMS," "Secondary constant-current RMS," "Secondary constant-power RMS," "Primary constant-current PEAK control," or "Constant-phase" to attain stable welding quality. -

Different setting can be set at each welding.

Pulsation, Upslope, Downslope and Weld stop. -

Power supply voltage fluctuation compensation control (effective when PULSE LIMIT is set)

The pulse limit is corrected according to the fluctuation in the power-supply voltage on the primary side.

This function is valid only in the primary constant-current PEAK control mode (PLM).

-

Up to five transformers can be connected with IS-300A by an optional MA-650A the transformer selector.

This function contributes to the improvement in productivity.- ◆Interrupt feature

Interrupt feature functions when a displacement amount reaches up to set level and stops current to obtain more stable fusing. For this feature, it needs to be connected with a weld checker with a built-in displacement monitor and set a displacement amount of electrodes beforehand. - ◆Program unit MA-660A (Sold Separately)

Employing an easily viewable color LCD. Current, voltage, or power can be monitored. - ◆Multilingual software

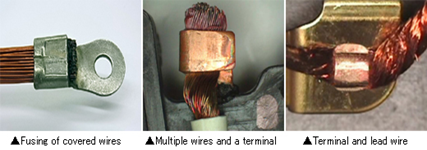

You can select the language from Japanese, English, Chinese, and Korean. - ◆Samples

| Model | IS-300A-00-00 | IS-300A-00-01 | |

| Power requirements (Fixed at ex-factory) | 3-phase, 200–240 VAC ±10% (50/60 Hz) |

3-phase, 380–480 VAC ±10% (50/60 Hz) |

|

| Max. output current | 300A (Peak value) | ||

| Number of schedules | 255 | ||

| Output frequency | 600Hz~3kHz (In 100 Hz increments) | ||

| Control method | Primary constant-current RMS Secondary constant-current RMS Secondary constant-power RMS Primary constant-current PEAK (with pulse width limit funcution) Secondary constant-voltage RMS Constant-phase control |

||

| Timer setting range | msec mode / cyc mode | ||

| SQUEEZE DELAY | 0000~9999ms / 000~999cyc | ||

| SQUEEZE | 0000~9999ms / 000~999cyc | ||

| UP SLOPE 1,2,3 | 000~999ms / 00~50cyc | ||

| WELD 1,2,3 | 000~999ms / 00~50cyc | ||

| DOWN SLOPE 1,2,3 | 000~999ms / 00~50cyc | ||

| COOL 1,2 | 000~999ms / 000~999cyc | ||

| HOLD | 00000~20000ms / 000~999cyc | ||

| OFF *1 | 0 or 0010~9990ms / 00~99cyc | ||

| Transformer turns ratio | 1.0~199.9 | ||

| Pulsation setting | 01~19 | ||

| Valve setting | 2 | ||

| Setting range (1)Constant current *2 (2)Constant power (3)Constant voltage (4)Constant phase |

(1)0.1~20.0kA (2)0.1~20.0kW (3)0.20~9.99V (4)10.0~99.9% |

||

| Current monitor | 00.0~99.9kA / 0.00~9.99kA | ||

| Power monitor | 000.0~999.9kW / 00.00~99.99kW | ||

| Voltage monitor | 0.00~9.99V | ||

| Pulse width monitor | HIGH 10.0~100% | ||

| Cooling method | Forced air-cooling | ||

| Data communication | RS-232C (One-way communication) / RS-485 (Bidirectional communication) |

||

| Operating environment | Ambient temperature | +5~+40℃ | |

| Humidity | 90% max. (no condensation) | ||

| Altitude | 1000m max. | ||

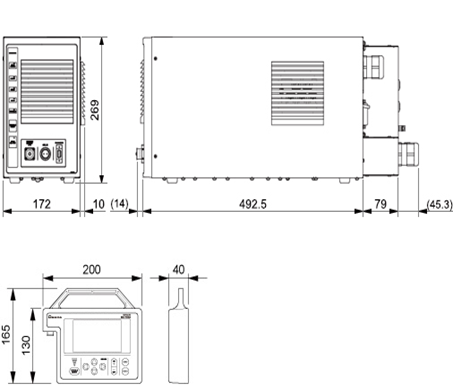

| Weight | 16.5kg | ||

- *1: No repetitive operation will be performed if “0” is selected for OFF (off time).

- *2: Primary current can be set up to 300 A.

| Model | ITH-651C6W | ITI-875A6W | SIT-F241-HC |

| Rated capacity | 26.8kVA | 37.1kVA | 75kVA (50%) |

| Rated primary voltage | 300V/600V | 300V | |

| No-load secondary voltage | 9.3V | 12.5V | 11.7V |

| Transformer turns ratio | 32:1/64:1 | 24:1/48:1 | 24:1 |

| Input frequency | 1kHz | ||

| Maximum welding current | 7000A | 7000A | 14400A |

| Duty cycle | 8.5% | 9% | 10% |

| Fan voltage | DC24V | ‐ | |

| Cooling method | Forced air-cooled | ||

| Weight | 16kg | 19kg | 35kg |

| Outline dimensions (mm) * | 168(W) x 398(D) x 199(H) | 168(W) x 446(D) x 199(H) | 180(W) x 495(D) x 240(H) |

* Include projections